Products

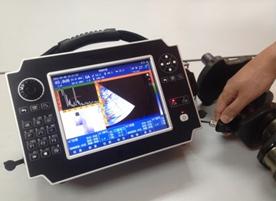

KPA-52A

KPA-52A is a portable 64-CH phased array ultrasonic flaw detector . It’s water&oil -proof , fan-free and with touch pad. Whole-process data logging, innovative phased array probes and inspection methods being the advantages, this model guarantees superior performance and support, which makes it among the best of its kind for high C/P ratio.

Working with the stylish wheel probe:

→ by touching or pressing to operate the instrument

→ fan-free heat dissipation; water&dust -proof

→ metallic housing against collision or tumble

→ linkage between scanner and the instrument

→ laser line to direct scanning

→ adjustable probe angle with scale inside the wheel

→ encoder to be installed on the probe

→a void left for a GPS unit in the middle of the scanner to be applied to tubeWorking with the stylish wheel probe:

Feature

I Dynamic Focusing

Dynamic Focusing Off Dynamic Focusing On

II TR Mode

Supportive of T-R mode, to make possible the solutions to PE and austenitic stainless steel, and a variety of applications such as tandem scanning, K-styled scanning, welded-seam TOFD scanning and thin-plate TR

III 3D Simulation Model

The 3D simulation scheme can be customized to offer one-for-all solutions.

IV APP Menu

Menu of the software is shown in the manner of APP.

It can be cut down or enlarged accordingly if asked by the users.

V Projected Capacitive Touch Screen

Projected Capacitive Screen, water&oil -proof, impervious to touching

Projected Capacitive Screen, water&oil -proof, impervious to touching

VI Metallic Housing

To strengthen the instrument, both shielding and heat-dissipating

VII Protective Pedestal

To prevent any damage to either the instrument or the object

Highlights

•16:64 PA Configuration and 2 Conventional Channels (T&R)

•3D simulation model, customizable with one-for-all solutions(instrument+probe+scenario)

•Image Smoothing

•Dynamic Depth-Focusing for high discernibility at different depths

•Omnisealed, water&dust -proof but capable of fan-free heat dissipation, over any adversities.

•Delay precision up to 2.5ns; evident inhibition on sidelobes as to enhance vertical and horizontal discernibility, as well as to improve imaging definition.

•Responsive A/L/S/C scan imaging; Encoder used for continuity of 100%-original-data logging .

•Supportive of ACG and TCG curves specified by ASME, to solve the problem of poor energy distribution and measurement accuracy.

•Focal laws to be automatically generated according to beam angle, focal length, scan mode, specs of probe and wedge, with auto-optimized angle stepping of S-scan.

•3 options of filtering: 0.5-9.7MHz、4.0-12.5MHz、6.7-20.8MHz; Auto Optimization of pulse width according to probe frequency; Excellent noise processing

•11-inch IG & WVGA (800x600) TFT display, touch pad, ensuring

nice visual effect outdoors or under strong sunlight.

•Ergonomic panel suitable for both hands operating; Hotkey parameters setting; USB port for instant data dump; HDMI port for external display of unlimited size.

•Host Software supplied for analysis, continuity of data logging, etc.

•AC/DC optional, allowing engagement of 2 pieces of battery collectively, in turn or by hot swap, to make sure duration of 6+ hrs.

Specification

Channel Configuration

PA : 16:64

UT : 2 CH

Physical Specification

Display: 11-inch 800X600 TFT color display

Transducer Ports: I-PEX 160-pin PA transducer port; Lemo-00

conventional transducer Port, for either T-R or T/R

I/O Ports: USB 2.0 (Qty:2) ; HDMI; LAN (GB Ethernet);

WIFI; GPS; GSM; 2D encoder

Registers: In-Built: 16G RAM+4GB FLASH SD card; External: USB drive

Weight: 5.5Kg (with batteries)

Dimension (mm): 298(L) x 198(H) x 106(W)

Power Supply: AC (100V-240V); DC(12V)

Charging: external charger

Battery Life: 6 hrs

Working Power: 24W

Language: English

IP: 54

Temperature Conditions: ambiance(-20℃~50℃);

storage(-20℃~60℃)

Performance Specification - PA

PRF: 50Hz~ 10kHz

Voltage: Bipolar ±45V ~±100V, 5V per step

Pulse Width: 20ns~ 800ns, 5ns per step

Damping: 50Ω

Sampling Rate: 100MHz

Delay Precision: 2.5ns

Rx Delay: 0us~ 40us

Bandwidth: 0.5MHz~ 20MHz

Gain: 0.0dB~ 90dB

Filter: 0.5~ 9.7MHz、4.0~ 12.5MHz、6.7~20.8MHz optional

Rectification: FW

Rejection: 0~ 80%

Scan Mode: L/S/C -scan

Triggering: Encoder

Scan Lines: Max 128

Angle: L-scan(-85°~ +85); S-scan (-85°~+85°)

Auto-Cal: TCG、ACG

Reach: 0.0mm~ 1000mm; min available (1mm)

Displaying Delay(Max): 1000mm

Unit: mm

Gate: A/B

Gate Start: available within the reach

Gate Width: available within the reach

Gate Height (Threshold): 5%~ 95%

Alarming: buzzer/LED

Measurement Spot: crest/flank

Readout: amplitude; beampath; horizontal; depth

Measurement Resolution: 0.5mm

Performance Specification - Conventional UT

PRF:50Hz~ 10kHz

Voltage: negative square wave -75V~-250V ; 25Vper step

Pulse Width: 20ns~800ns; 5ns per step

Damping: 80Ω、400Ω

Sampling Rate: 200MHz

Bandwidth: 0.5MHz~ 15MHz

Gain: 0.0dB~ 110.0dB

Filter: wideband; narrowband

Rectification: FW

Rejection: 0~ 80%

Scan Mode: A-scan

Auto-Cal: DAC/AVG

Reach: 0.0mm~ 2000mm

Displaying Delay (Max): 2000mm

Displaying Shift (Max): 2000mm

Unit: mm

Gate: A/B

Gate Start: available within the reach

Gate Width: available within the reach

Gate Height (Threshold): 5%~ 95%

Alarming: buzzer/LED

Measurement Spot: crest/flank

Readout: amplitude/beampath/horizontal/depth

Measurement Resolution: 0.1mm

Showcase Album Small-Dia Tube

Applications

◇Common or special welded seams of steel structure, utility boiler, pressure vessel, pipeline, nuclear power infrastructures, watercraft, oil tank, ethylene tube, etc.

◇Railway welded seams, locomotive wheel sets and axles.

◇Aluminum alloy FSW butts and bondings of composites used in aerospace industry.

◇Blades and bolts used in power industry.

◇Cases when there’s not enough space for movement whilst inspection; Cases when conventional UT is preferred.